The Importance of Medical Packaging Paper in Ensuring Product Safety and Sterility

Release time

2025-02-14

In the medical industry, where the stakes are incredibly high and the margin for error minimal, the role of packaging cannot be overstated. Among the various types of packaging materials used, Medical Packaging Paper plays a pivotal role in ensuring the safety, sterility, and integrity of medical devices and pharmaceuticals. This article delves into the significance of medical packaging paper, highlighting its unique properties, applications, and the stringent standards it must meet to safeguard public health.

Medical Packaging Paper is specifically designed to meet the rigorous requirements of the medical field. Unlike ordinary packaging paper, it is manufactured using high-quality raw materials such as polyester fibers and acid-free pulps, which impart it with superior barrier properties against moisture, oxygen, and microorganisms. These characteristics are crucial in maintaining the sterility of medical devices and preventing contamination during storage and transportation.

One of the key features of Medical Packaging Paper is its ability to provide a microbial barrier. In the context of medical packaging, this means that the paper must be capable of preventing the ingress of bacteria, fungi, and other microorganisms that could compromise the sterility of the packaged product. This is particularly important for devices and pharmaceuticals that are intended for implantation or direct contact with the patient's bloodstream, as even a minute contamination can have severe consequences.

Moreover, Medical Packaging Paper must exhibit excellent sealability and strength. The packaging must be able to withstand the rigors of sterilization processes, such as steam sterilization, ethylene oxide sterilization, or gamma radiation, without compromising its integrity. The seal between the paper and any plastic films or foils used in combination must be robust enough to prevent leakage and maintain the sterile environment within the package.

The applications of Medical Packaging Paper are vast and varied. It is used in the packaging of medical devices ranging from syringes and needles to surgical instruments and implants. It is also essential in the packaging of pharmaceuticals, including tablets, capsules, and vials, ensuring that they remain sterile and uncontaminated until they are ready for use.

Furthermore, with the increasing focus on sustainability and environmental responsibility, Medical Packaging Paper is being developed using more eco-friendly materials and processes. Manufacturers are striving to reduce the environmental footprint of their products while maintaining the high standards of safety and sterility required by the medical industry.

RELATED NEWS

Baking Paper: An Essential Tool in the Kitchen

Baking paper is a staple in every kitchen, and it plays a crucial role in the baking and cooking processes.

Reinforced Medical Paper RCP83: A New Era in Medical Supplies

Reinforced medical paper RCP83 is emerging as a significant innovation in the medical field.

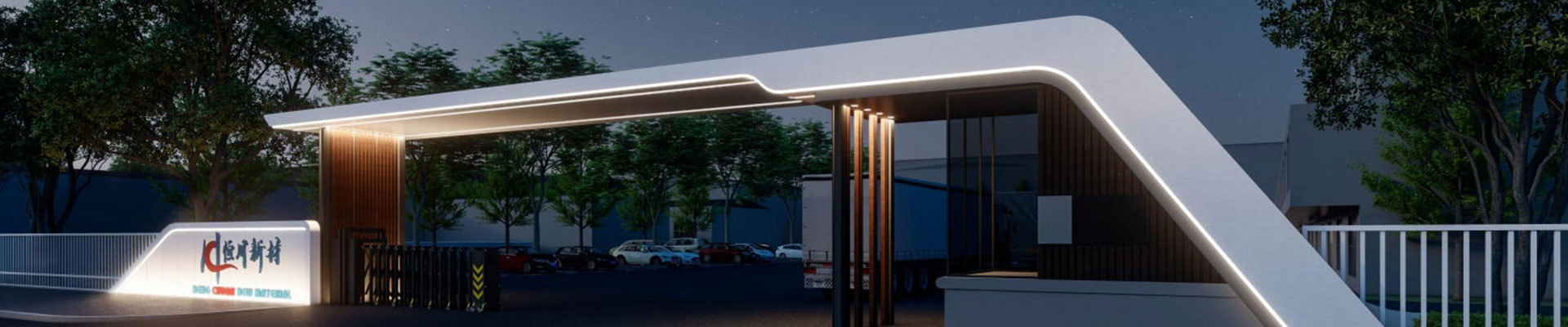

Hengda New Material: A Consistent Presence at CMEF and EXPOMED Fairs

Zhejiang Hengda New Material constantly attends the fair of CMEF and EXPOMED.

Another important aspect of straw base paper is its versatility. It can be used for a wide range of applications, including packaging, printing, and writing.

The Significance and Applications of Medical Wrapping Paper

Medical wrapping paper serves as a reliable barrier to maintain the sterility of these items.

The Versatile Applications of Greaseproof Kraft Paper in Modern Industries

Greaseproof Kraft Paper is a specialized type of packaging material designed to resist oil, moisture, and heat, making it ideal for industries requiring durable and hygienic solutions.